- L&T GreenTech

- Our Offerings

- Electrolysers

L&T Electrolysers Ltd. is a global OEM leading the clean energy transformation through advanced electrolyser manufacturing. Backed by L&T’s global engineering, manufacturing and construction expertise, we deliver high-performance, reliable, and scalable solutions that enable efficient Green Hydrogen production for industries worldwide.

Our world-class manufacturing facility is designed to produce pressurised alkaline electrolysers based on next-generation European technology. Built to international quality and performance standards, our systems combine exceptional durability, operational flexibility, and thermal stability. Designed for seamless integration with renewable energy sources, they deliver fast response, high availability, and consistent hydrogen output supporting scalable, reliable, and commercially viable hydrogen projects worldwide.

Aligned with the Make in India and Aatmanirbhar Bharat initiatives, we have achieved over 80% indigenisation, supported by a robust network of qualified Indian suppliers. Every electrolyser reflects global standards of quality, safety, and performance — built locally, trusted globally.

With end-to-end control over the value chain, from design and stack manufacturing to testing and deployment, L&T Electrolysers assures competitiveness, supply chain resilience, and world-class service support.

Our scalable and modular electrolysers offer highly adaptable solutions tailored to the evolving needs of industrial processes, mobility, and Power-to-X applications, enabling efficient and future-ready green hydrogen deployment across diverse use cases.

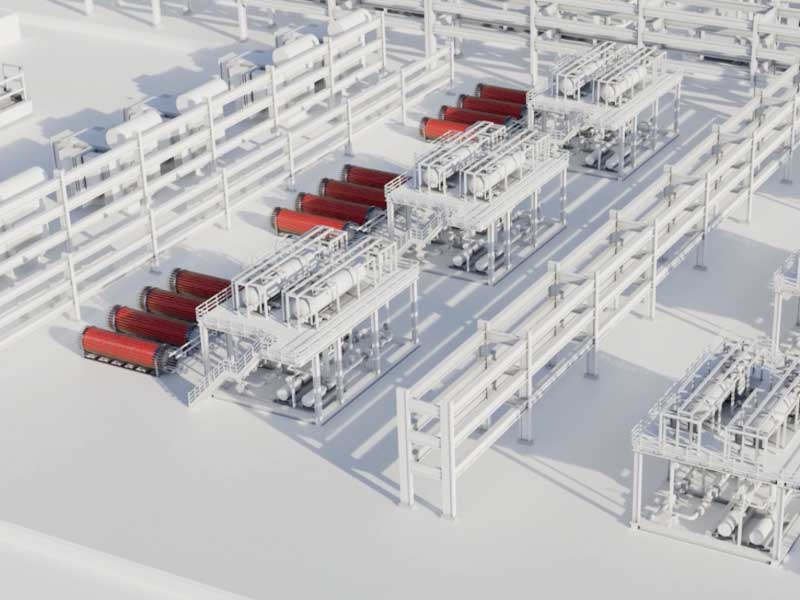

96 MW Cluster

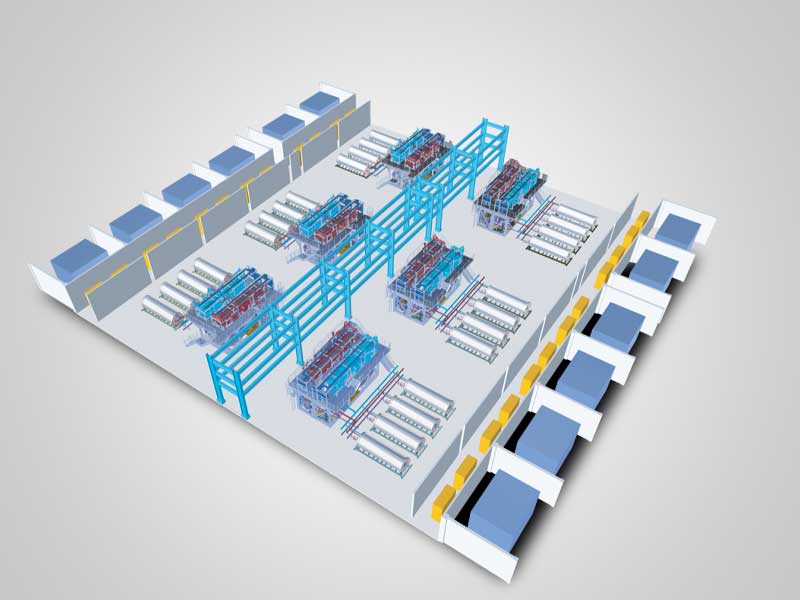

24 MW Cluster

| Power Class | 1 MW | 2 MW | 4 MW | 8 MW | 16 MW |

| System Design Life (Mechanical) | + 20 Years | ||||

| H2 Flow Rate | 200 Nm³/hr | 400 Nm³/hr | 800 Nm³/hr | 1,600 Nm³/hr | 3,200 Nm³/hr |

| H2 Purity | > 99.999% after HPS | ||||

| O2 Purity | 99% at Electrolyser Outlet | ||||

| H2 & O2 Delivery Pressure | ~ 26 – 28 bar (g) | ||||

| Stack DC Energy Consumption | 4.2 – 4.5 kWh/Nm³ | ||||

| Operating Range | 20 – 100% | ||||

| Reaction Time | < 30 / 60 s from hot stand-by to 100% | ||||

| Ramp-Up / Down | > 5%/s | 20%/s | ||||

L&T Electrolysers has commenced commercial-scale manufacturing of alkaline electrolysers at its state-of-the-art facility in Hazira, Gujarat, India. Engineered to meet stringent European and international quality, safety, and industrial standards, the facility is designed to support gigawatt-scale green hydrogen projects for global markets.

Located within the A. M. Naik Heavy Engineering Complex, Hazira, the facility reflects L&T’s globally recognised engineering excellence and execution capability.

The manufacturing ecosystem is designed for precision, efficiency, and scalability, delivering consistent, repeatable, and bankable outcomes. End-to-end in-house capabilities span fabrication, precision machining, automated component manufacturing, electrolyser cell and stack assembly, system integration, and full-capacity testing.

High levels of automation, robotics, and digitalization ensure uniform quality, high throughput, and long-term reliability.